Autoclave curing process produces highest level of all composite products. It is applied to aircraft primary structures, or high-end automobiles

OOA methods save energy, labor hours, and investment

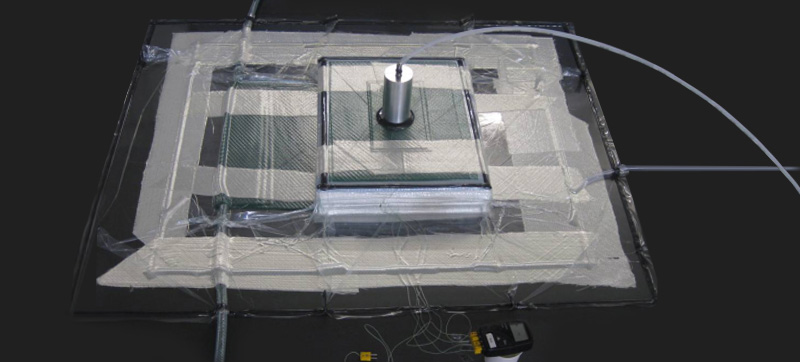

T-50 Vertical Fin Specimen Manufacturing

VARTM impregnates matrix resin into reinforcement fiber using vacuum force.

It is simpler and cheaper method than autoclave curing. But because of its limited mechanical properties, this method is mainly is used for interiors or Secondary structures.

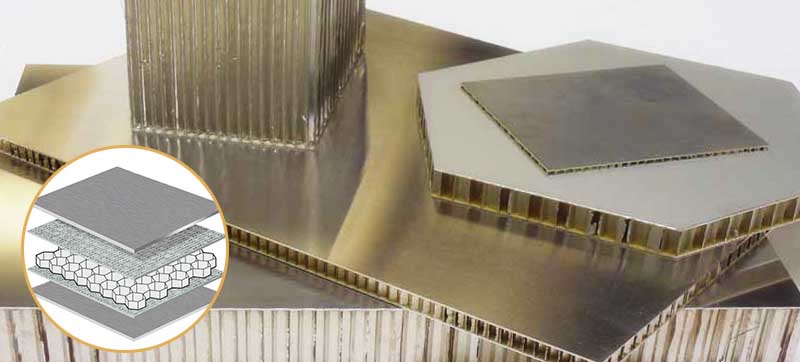

Metal bonding is an essential technology for control surfaces structures of aircraft. Chemical surface treatment, such as PAA or CAA, is required prior to bonding process.

Adhesive Film Metal bonding is the process that improves performance of metal physicochemically by bonding metal to metal using adhesive film. There is two types of process ‘Bonding two or more metals’, ‘Sandwich structure manufacturing the core is inserted between the metals’.

All metal surface should be chemically treated to remove contaminant and improve adhesion. In case of Aluminum, FPL etching, Phosphoric Acid Anodizing(PAA) or Chromic Acid Anodizing(CAA) process can be applied.